In the not-so-distant future, the year 2030, a revolutionary material known as biosynthetic spider silk is poised to revolutionize industries across the globe. This material, derived from the DNA of spiders, has the potential to outperform traditional synthetic fibers in terms of strength, flexibility, and biodegradability. This article delves into the advancements made in mass-producing biosynthetic spider silk and explores the rigorous strength and consistency tests that ensure its reliability.

**The Rise of Biosynthetic Spider Silk**

Biosynthetic spider silk has garnered attention due to its exceptional properties, which are unmatched by any naturally occurring or synthetic materials. This silk boasts a tensile strength that surpasses steel on a weight-for-weight basis, while also being lightweight, flexible, and capable of being woven into various forms. These attributes make it an ideal candidate for use in a wide array of applications, including aerospace, medical, and fashion industries.

**Mass Production Techniques**

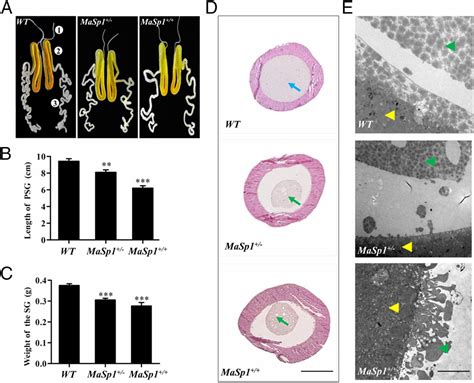

To bring biosynthetic spider silk to the mass market, innovative mass production techniques have been developed. These methods involve isolating the silk-producing DNA from spiders and then inserting it into microorganisms, such as bacteria or yeast, which can then produce the silk protein in large quantities. This approach has allowed researchers to scale up production while maintaining the quality and properties of the original silk.

One of the key advancements in mass production is the development of biofactories, which are bioreactors designed to cultivate microorganisms and produce silk protein. These biofactories can operate continuously, ensuring a steady supply of biosynthetic spider silk for various applications.

**Strength and Consistency Tests**

To ensure the quality and reliability of biosynthetic spider silk, rigorous testing is conducted. These tests focus on the material’s strength and consistency, which are crucial for determining its suitability for specific applications.

**Strength Tests**

Strength tests involve subjecting samples of biosynthetic spider silk to various stressors to measure their ability to withstand forces without breaking. This includes tensile strength tests, where samples are pulled apart until they break, and flexural strength tests, which evaluate the material’s ability to resist bending forces.

The results of these tests have shown that biosynthetic spider silk consistently outperforms traditional materials, with tensile strengths that can reach up to 1.5 gigapascals. This makes it a highly desirable material for applications that require extreme strength, such as aerospace components and medical devices.

**Consistency Tests**

Consistency tests are crucial for ensuring that the biosynthetic spider silk produced in large quantities maintains the same quality and properties as smaller-scale batches. These tests include color, diameter, and elasticity tests to assess the uniformity of the material.

One of the most challenging aspects of consistency testing is to ensure that the silk produced by different microorganisms or in different biofactories exhibits the same properties. Advanced analytical techniques, such as Fourier Transform Infrared Spectroscopy (FTIR) and Raman Spectroscopy, have been employed to analyze the molecular structure of the silk and verify its consistency.

**Future Prospects**

As biosynthetic spider silk production continues to advance, the material is expected to play a pivotal role in various industries. Researchers are already exploring its potential applications in areas such as:

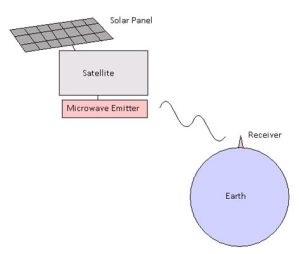

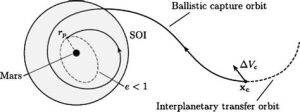

– Aerospace: For use in lightweight, durable components, such as aircraft fuselages and satellite structures.

– Medical: For creating biocompatible sutures, tendons, and ligaments that can reduce healing times and minimize scarring.

– Fashion: For developing sustainable and comfortable fabrics that can be recycled and reused.

In conclusion, biosynthetic spider silk is set to transform industries in 2030 and beyond. With its exceptional strength, flexibility, and biodegradability, this material has the potential to revolutionize the way we produce and use materials. As mass production techniques continue to evolve and strength and consistency tests ensure reliability, biosynthetic spider silk is poised to become a game-changer in the years to come.