Introduction:

In the ever-evolving world of construction and infrastructure, the need for advanced materials and technologies has become more pronounced than ever before. One such innovation that is set to revolutionize the industry is programmable cement, which is expected to be fully developed by 2025. This article delves into the concept of programmable cement, its potential applications, and its role in detecting cracks in infrastructure.

What is Programmable Cement?

Programmable cement, also known as self-sensing cement, is a type of cement that can be engineered to have specific properties and functions. Unlike traditional cement, which is a purely inorganic material, programmable cement can incorporate additives and nanoparticles that can alter its mechanical, electrical, and thermal properties.

The development of programmable cement is driven by the need for smarter, more sustainable, and efficient infrastructure. By modifying the cement’s composition, engineers can create materials that can adapt to changing environmental conditions, improve durability, and even detect structural issues such as cracks.

Applications of Programmable Cement:

1. Self-healing concrete: One of the most promising applications of programmable cement is the creation of self-healing concrete. By incorporating healing agents and sensors into the cement mixture, cracks can be detected and repaired automatically, reducing maintenance costs and extending the lifespan of infrastructure.

2. Smart bridges and roads: Programmable cement can be used to construct bridges and roads that can monitor their own structural health. By embedding sensors within the cement, engineers can detect cracks, deformations, and other issues in real-time, allowing for timely repairs and maintenance.

3. Sustainable buildings: Programmable cement can also be used in the construction of sustainable buildings. By adjusting the cement’s thermal properties, buildings can be designed to regulate temperature and reduce energy consumption.

4. Underground infrastructure: The ability of programmable cement to detect cracks makes it an ideal material for underground infrastructure, such as tunnels and pipelines. This can help prevent leaks, collapses, and other hazardous situations.

Crack Detection with Programmable Cement:

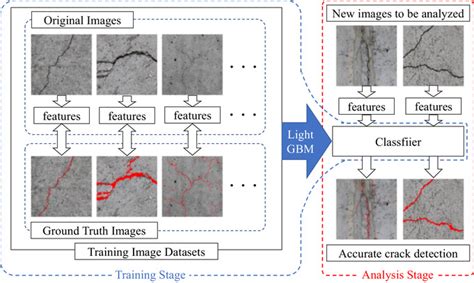

One of the most significant advantages of programmable cement is its ability to detect cracks in infrastructure. This is achieved through the integration of sensors and smart materials within the cement mixture.

1. Electrochemical sensors: These sensors can detect the presence of cracks by measuring the electrical resistance across the material. When a crack forms, the electrical resistance increases, indicating a potential issue.

2. Piezoelectric sensors: These sensors convert mechanical stress into electrical signals. When a crack forms, the piezoelectric sensor detects the stress and generates an electrical signal that can be used to identify the crack’s location and size.

3. Optical sensors: These sensors utilize light to detect cracks by measuring the refractive index of the cement. Changes in the refractive index can indicate the presence of cracks.

Conclusion:

Programmable cement is a groundbreaking material that has the potential to transform the construction and infrastructure industry. With its ability to self-sense and detect cracks, programmable cement can lead to smarter, more sustainable, and efficient infrastructure. As we approach 2025, the development of programmable cement will undoubtedly play a crucial role in ensuring the safety and longevity of our built environment.