In the fast-paced world of pharmaceutical production, advancements in technology are continuously pushing the boundaries of efficiency and safety. One such groundbreaking innovation is the use of acoustic levitation in the production of pharmaceuticals. By 2027, we can expect to see contactless pharmaceutical production lines revolutionizing the industry. This article explores the potential of acoustic levitation in pharmaceutical production and its implications for the future.

**Understanding Acoustic Levitation**

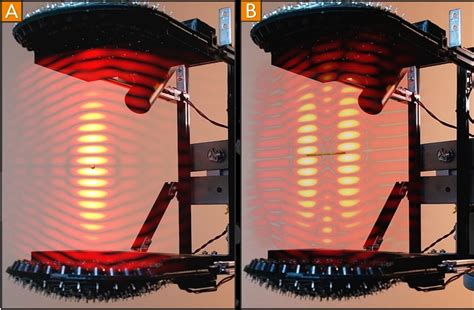

Acoustic levitation, also known as sonolevitation, is a technique that uses sound waves to create an acoustic field. This field can generate forces that are sufficient to counteract gravity and hold objects, such as particles, in mid-air without any physical contact. The concept is based on the principle of the Doppler effect, where the frequency of sound waves is altered due to the relative motion between the source and the observer.

**Applications in Pharmaceutical Production**

In the pharmaceutical industry, acoustic levitation offers numerous advantages over traditional production methods. The most significant of these is the ability to produce drugs without physical contact, which is crucial for maintaining product quality and minimizing the risk of contamination.

Here are some key applications of acoustic levitation in pharmaceutical production:

1. **Drug Synthesis**: Acoustic levitation can be used to synthesize drugs in a controlled environment, ensuring uniformity in particle size and shape. This leads to improved drug efficacy and reduced side effects.

2. **Crystallization**: By controlling the acoustic field, pharmaceutical companies can achieve precise control over the crystallization process, resulting in higher purity and yield of active pharmaceutical ingredients (APIs).

3. **Tablet Manufacturing**: Acoustic levitation can be used to produce tablets with consistent size and shape, reducing the variability in drug dosage and enhancing patient safety.

4. **Formulation Development**: The technique can also be employed in the development of novel drug formulations, such as inhalable powders or liquid suspensions.

**Contactless Production Lines**

By 2027, we can expect to see the emergence of contactless pharmaceutical production lines powered by acoustic levitation. These lines will feature several key components:

1. **Acoustic Levitation Chambers**: These chambers will house the acoustic levitation equipment, where particles and materials will be processed in a controlled environment.

2. **Automated Systems**: The production lines will be equipped with advanced automation systems to ensure precise control over the acoustic fields and other process parameters.

3. **Quality Control Systems**: Continuous monitoring of the production process will be essential to ensure the quality and consistency of the final products.

4. **Integration with Existing Facilities**: The contactless production lines will be designed to integrate with existing pharmaceutical manufacturing facilities, minimizing disruptions to the supply chain.

**Benefits of Contactless Production Lines**

The adoption of contactless pharmaceutical production lines powered by acoustic levitation will offer several benefits, including:

1. **Reduced Contamination Risk**: By eliminating physical contact between particles and equipment, the risk of contamination is significantly reduced.

2. **Improved Product Quality**: The controlled environment and precise control over the process parameters will lead to higher purity and consistency in drug production.

3. **Increased Efficiency**: The contactless nature of the process will result in shorter production times and lower energy consumption.

4. **Scalability**: The technology can be easily scaled up to meet the demands of large-scale pharmaceutical production.

In conclusion, acoustic levitation is poised to transform the pharmaceutical industry by enabling the development of contactless production lines. By 2027, we can expect to see these innovative lines revolutionizing the way drugs are manufactured, offering numerous benefits for both pharmaceutical companies and patients.